Do you have questions?

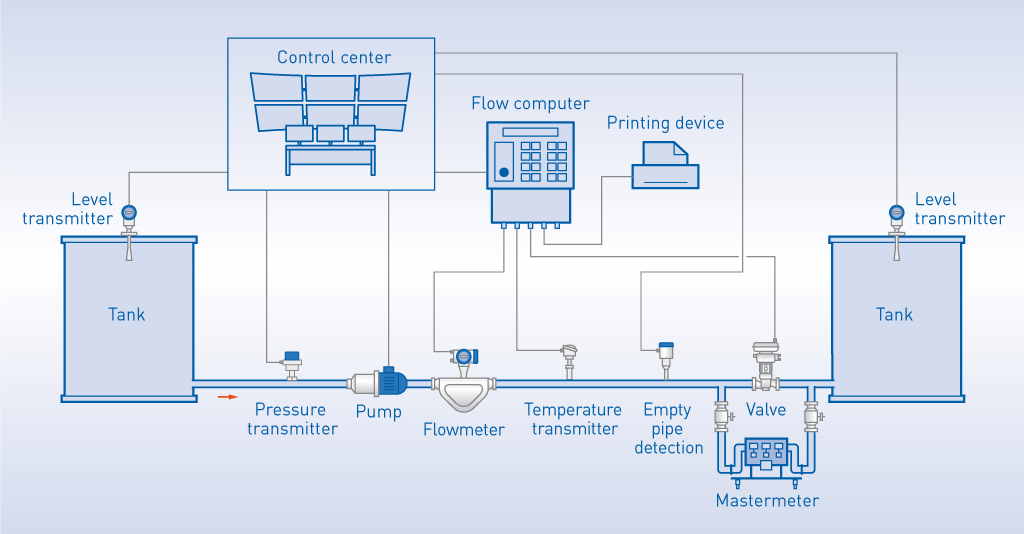

Pipeline Flow Measurement with Process Control

To achieve a solution with automated control of the delivery quantity, a flow computer is used to monitor the amount of liquid transferred, and controls the pump and valves to deliver a pre-set quantity, as required by the purchaser. This eliminates the obligation for both parties being needed to attend on site, to monitor and sign off on the quantity actually delivered. The flow computer can also record the calibration data from the flowmeter, including any adjustments to its operational parameters, as well as highlight any need for scheduled recalibration. In this way the need for supervisory and qualified personnel from both parties to attend site is greatly reduced: the flow computer becomes an integral part of the flowmeter system, and needs to be approved by the calibration authority.

The medium is still transported from one container (the seller) to another container (the buyer) via a pipeline. Both parties can access the stored data in the process control system memory to see the actual measurements. Again, level measurement systems in the storage tanks or containers are used to prevent any gas entrainment from a low liquid level in the supply tank, or overfilling of the receiving tank. The pipeline may also be equipped with additional measuring devices, such as pressure and temperature measuring devices or empty pipe detection sensors: all the signals from these sensors, plus the flowmeter and the level gauges are recorded within the process control system.