Do you have questions?

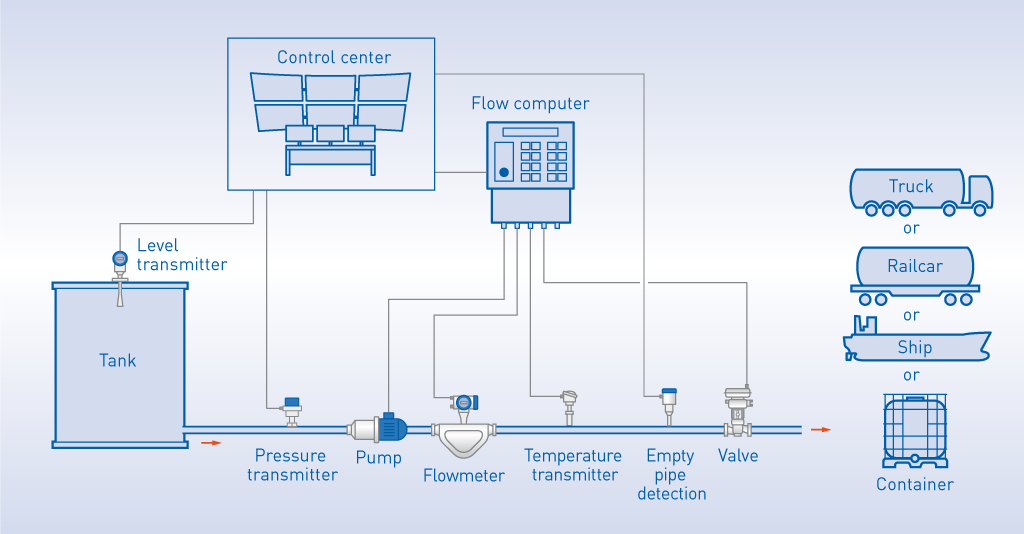

Loading Plant with Level Measurement

As an alternative approach to the previously described system using a gas separator, this is another system for loading a tank truck, tank car or ship with liquid products for onward delivery. The product is piped directly from a storage tank to the delivery bay. To prevent any gas pockets entering into the pipeline, the level of the tank contents must not drop below a pre-set minimum value. This is achieved by monitoring the tank contents using a radar level measurement system, which monitors the tank contents and signals an alarm when the level falls too low.

The control centre computer is programmed to deliver a preselected amount of product to the tanker in the loading area, and controls the valves and pump to start the delivery. The amount delivered is monitored by the flow meter, via the flow computer, which is approved suitable for this duty by the appropriate calibration authority. The delivery continues at a suitable rate of flow, subject to there being no low level alarm signal from the level sensor in the storage tank. When the delivery is complete, the batch number, quantity and data from the other sensors in the delivery line, like pressure and temperature, are monitored, and stored in the computer memory. Likewise, the measurement results can be printed out for the delivery tanker driver, by means of a calibration-approved printer, which is also connected to the flow computer.