Do you have questions?

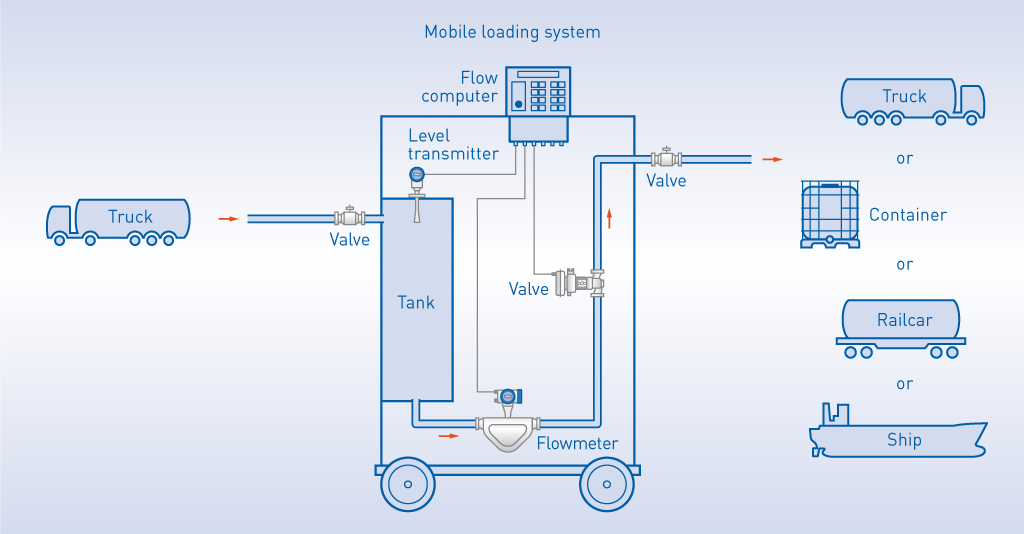

Mobile loading system

A Mobile Loading System is often used so that on receiving a bulk liquid delivery from a road tanker, or other delivery tank system, the receiving plant manager can cross check the delivery quantity shown by the supplier, or the metering system on the tanker. The mobile loading system is mounted on a moveable skid, which is brought to the tanker and connected between the tanker discharge point and the container or tank where the product is to be stored. To prevent gas inclusions invalidating the flowmeter reading, the first element of the loading system is a settling tank, which must not fall below a minimum contents level. This level is monitored using a radar gauge on the tank.

The liquid flow is measured by a calibrated flowmeter: the measurement results are stored by a flow computer, also approved by a legal calibration authority. The flow computer may also control a pump and / or a valve, to adjust the flow rate out of the settling tank. The measurement results can be printed out by a licensed printer, which is connected to the flow computer when required. The loading system can additionally monitor other parameters of the delivered product, such as pressure and temperature. All the measurements are stored in the flow computer and can be transmitted to the overall plant control system.